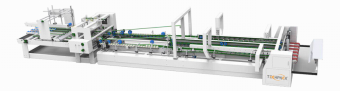

Feeder

Upper/lower belt adjust for 3/5ply board

Motorized setting glue application position

Equipped with scrap cleaning device

Gluer: Glue wheel or optional VALCO spray glue system

Folder gluing part

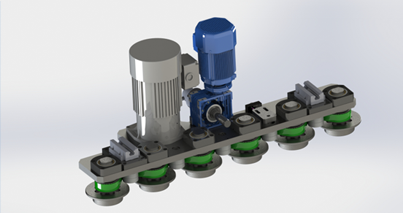

Two servo motors for belt and two servo motors for alignment wheels

Vacuum transfer for main belt to avoid board slippery and eliminate fishtail problem

Two strong upper beams and lower beam with maximum high speed running stability

Side pressure rely on the folding blade for more accurate folding line

In the middle of the folding beam, 90°correcting wheels are equipped for controlling the folding angle

Lower folding belts are driven by servo motors and speed adjustable

Folding beam with auto motorized control

Gantry structure to ensure machine stability at high running speed

Every beam equipped alignment wheels for better box shaping

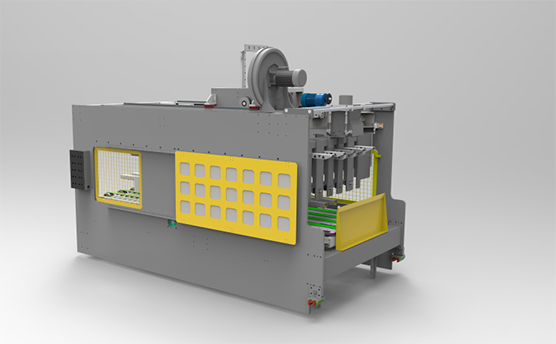

Counter ejector

Photo sensor for precise counting

Five servo motors for precise counting, stacking and ejecting at high running speed

Pneumatic stacking and powerful blower for better alignment of boards

Rear baffle can be adjusted according to board size

Upper conveyor belt position can be adjusted automatically or manually according to board stacking height

The ejection part can move left/right to ensure the boxes are stacked in center of the machine